Amanda Germaine On The Value Of An In-House Lab

Today, Amanda talks about how the in-house lab at Longworth Dental benefits the patient. She discusses the different pieces of technology involved in creating crowns, night guards, ortho fabrications, and bleaching trays.

The lab allows us to do everything in-house.

The advantage for the patient is quicker turnaround time and the dentist can look at the design quicker. Instead of two weeks, they can look at it the same day. If you lose an aligner, we can usually get it back to you the same day. Who doesn’t want that kind of customer service?

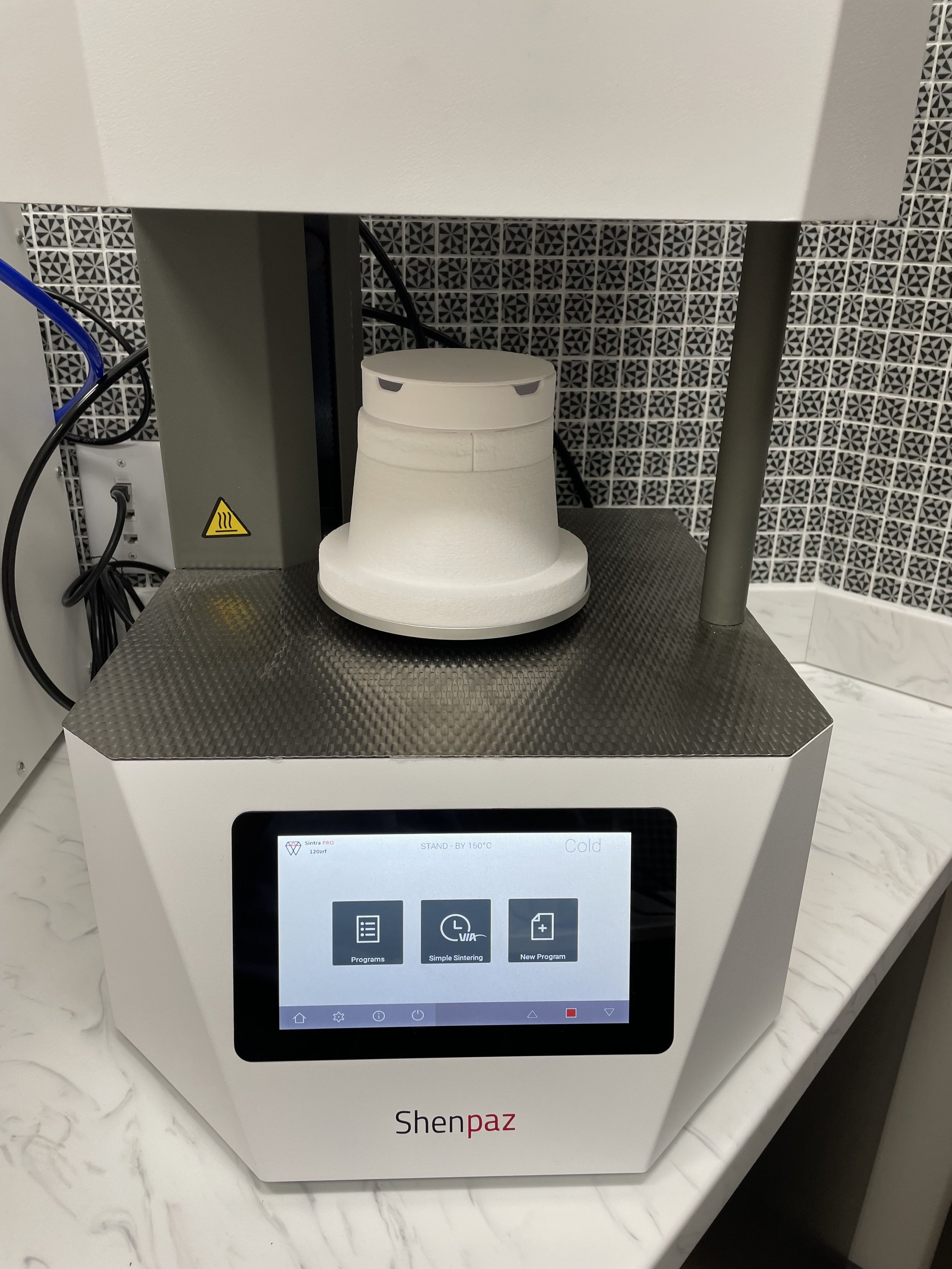

Let me take you for a little tour of our lab. When you come in, we have a sintering furnace. When you stain a crown, it has to go in this furnace at a very high temperature, at least 900 degrees, to bake it. It takes about 20 minutes.

Longworth Dental’s Sintering Furnace

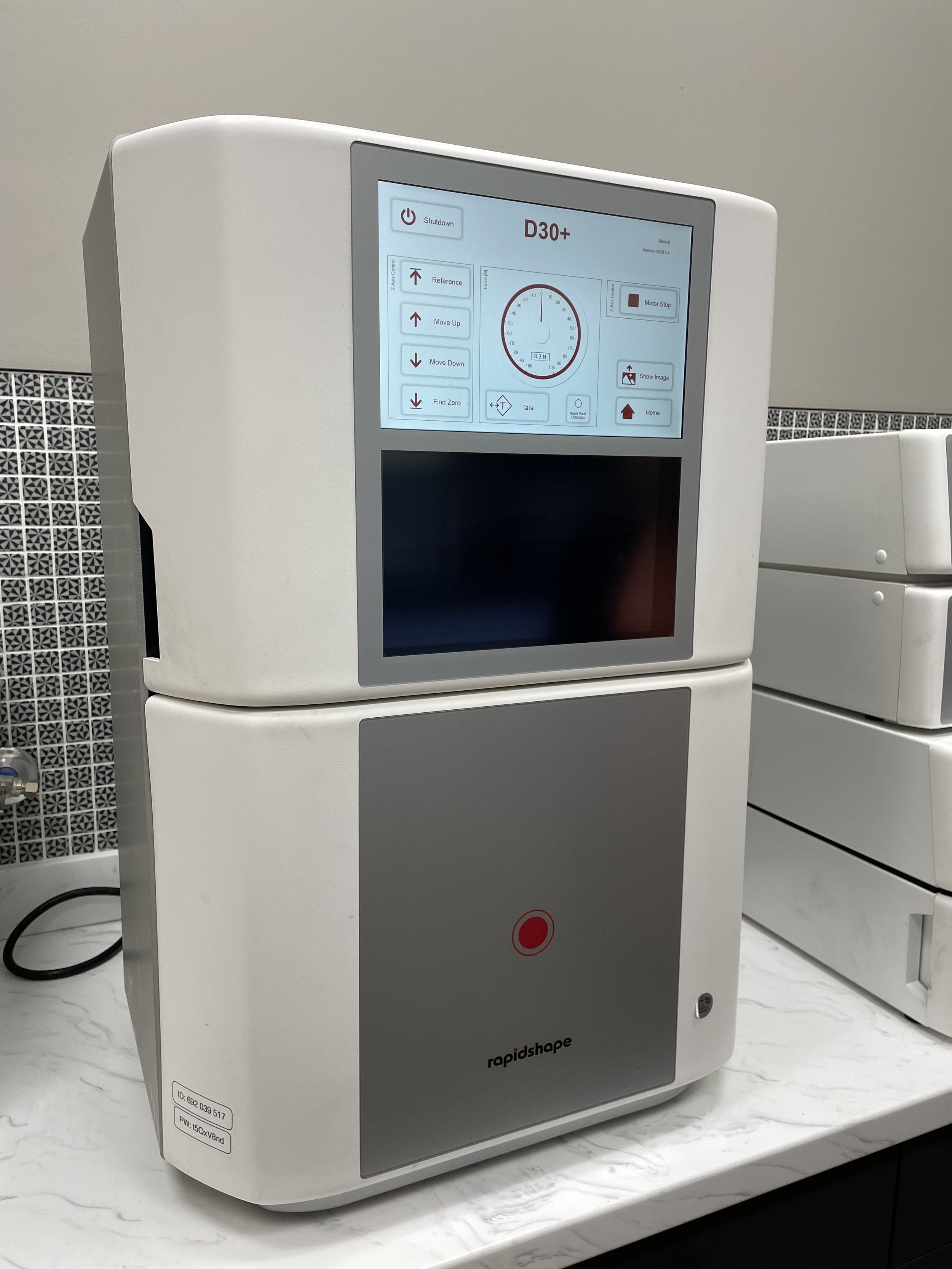

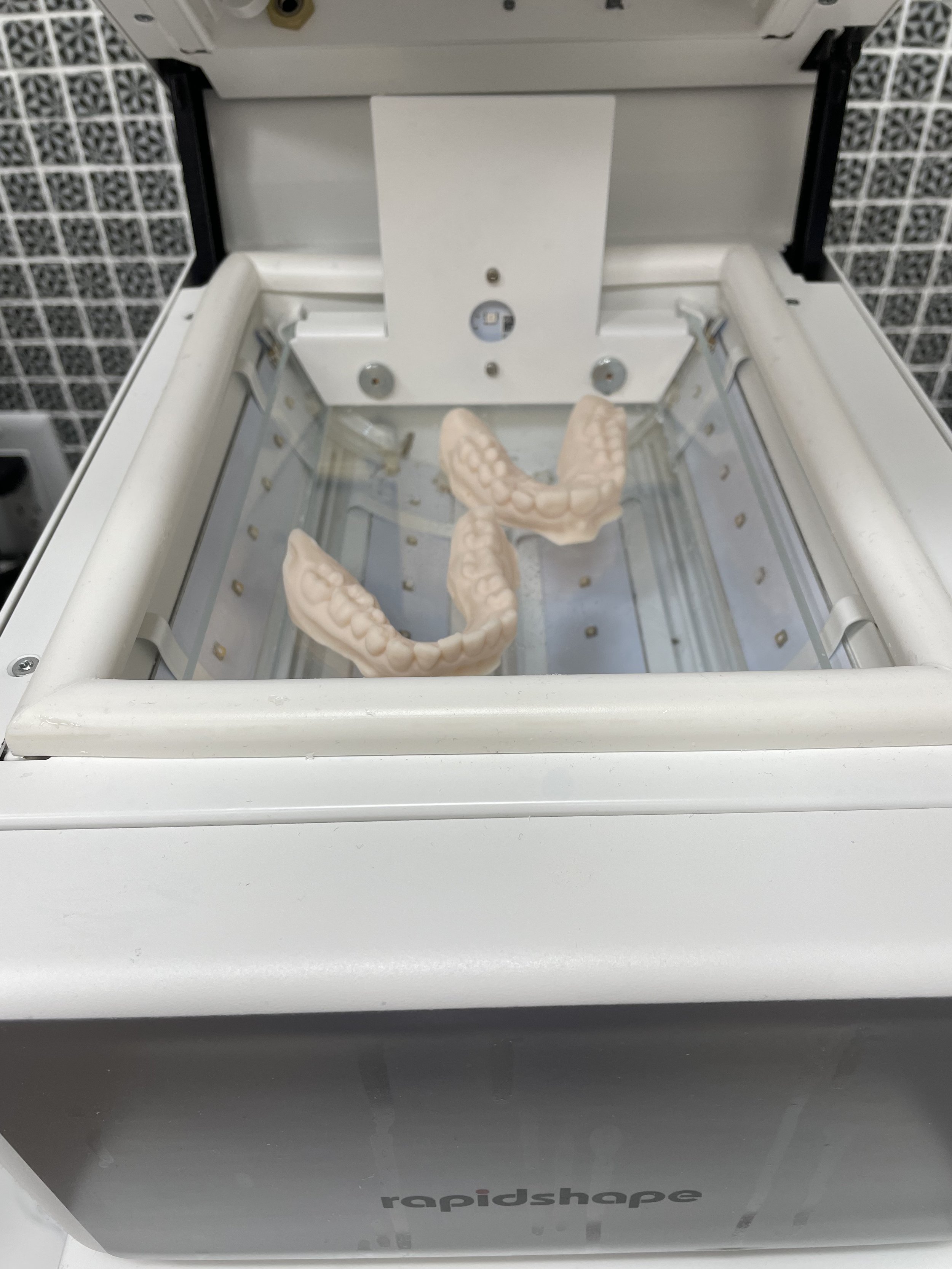

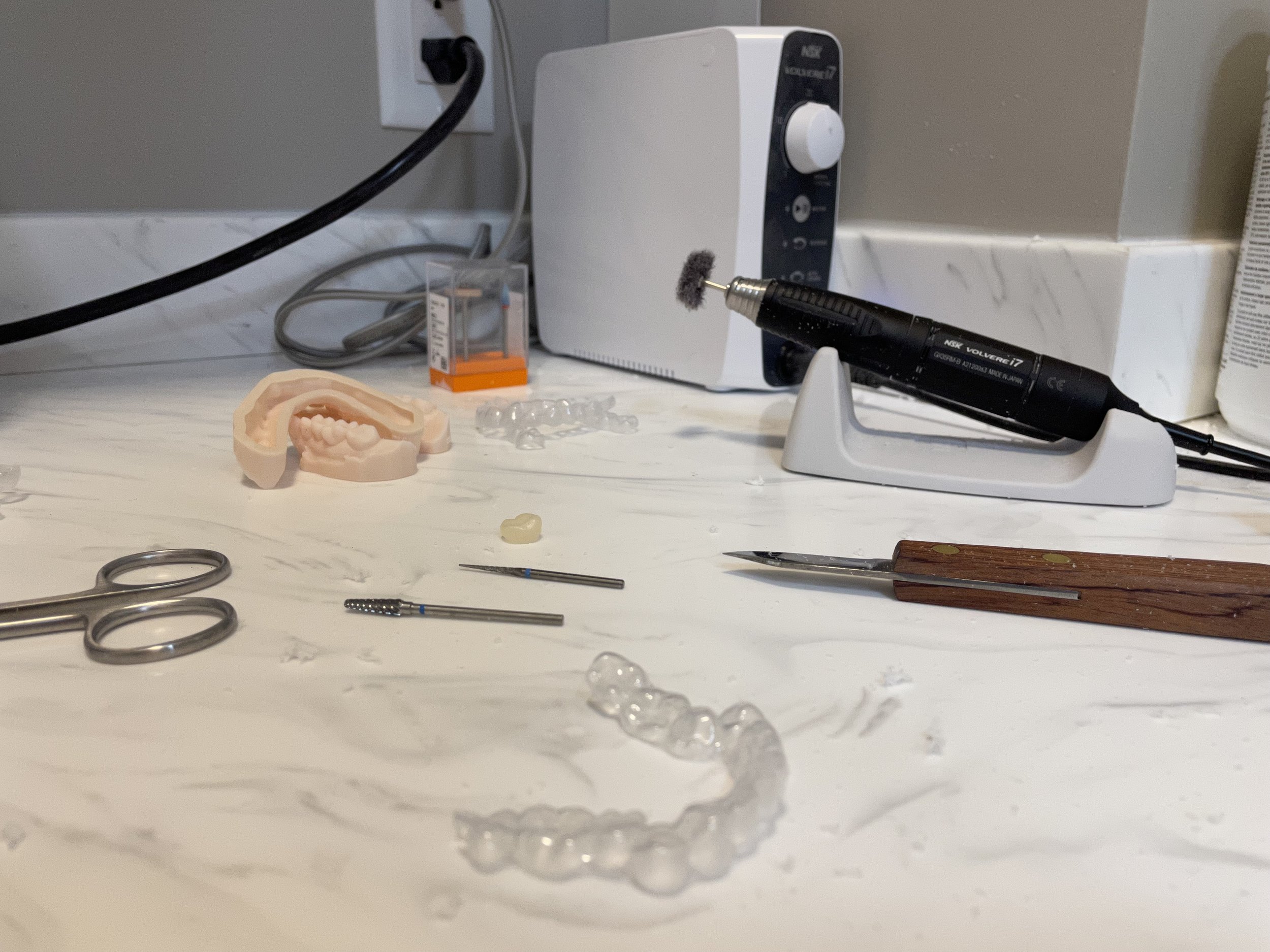

If we continue on, we have our Rapid Shape 3D printer. We 3D-print models and night guards. At the moment, a model takes about 40 minutes to print, from the base all the way down to the incisal parts of the teeth, the very top of the tooth, the biting surface. It uses a laser and prints it that way. Night guards take 2.5 hours to print; they are made with a different material than model material, which is safe for the mouth.

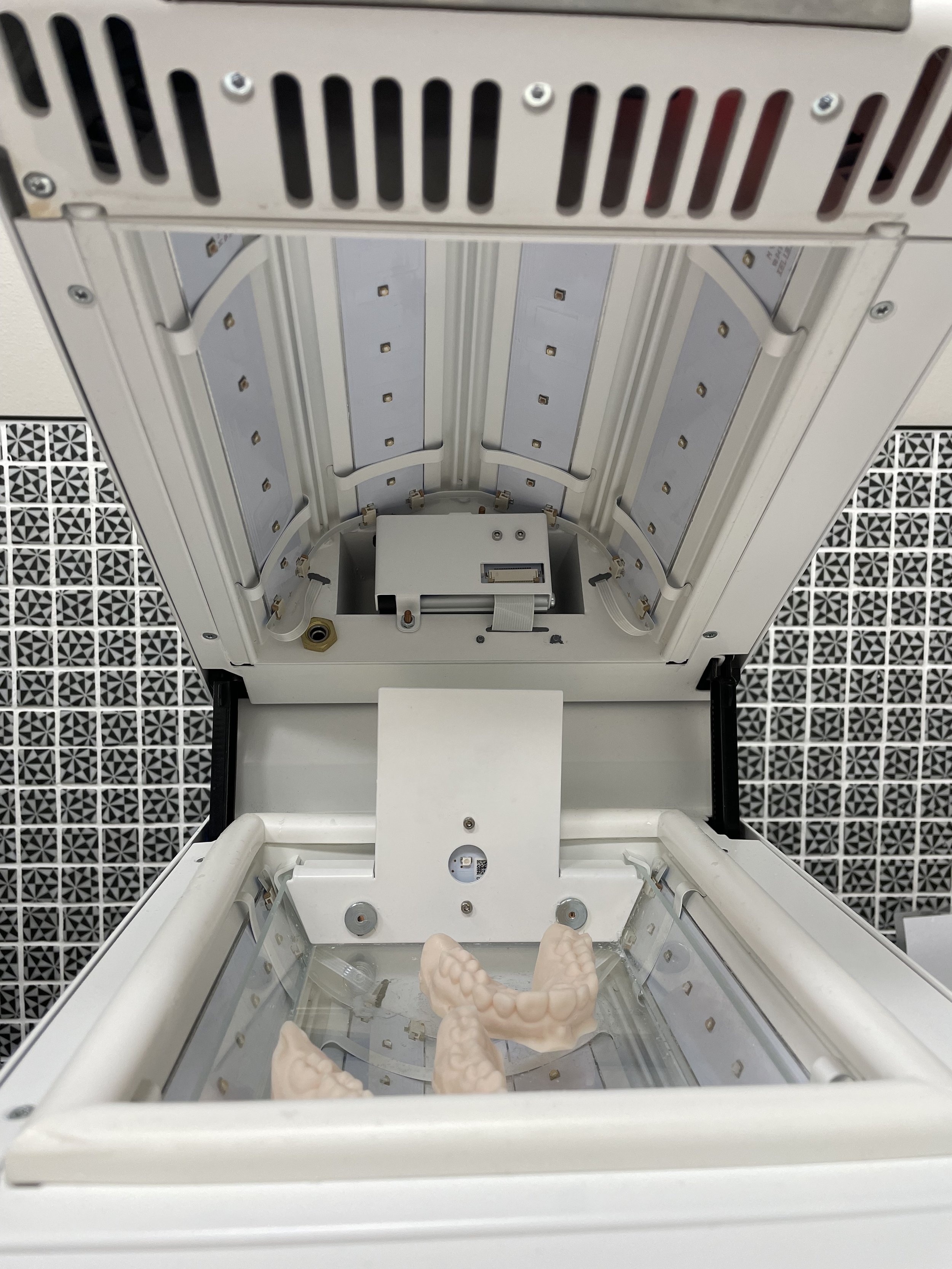

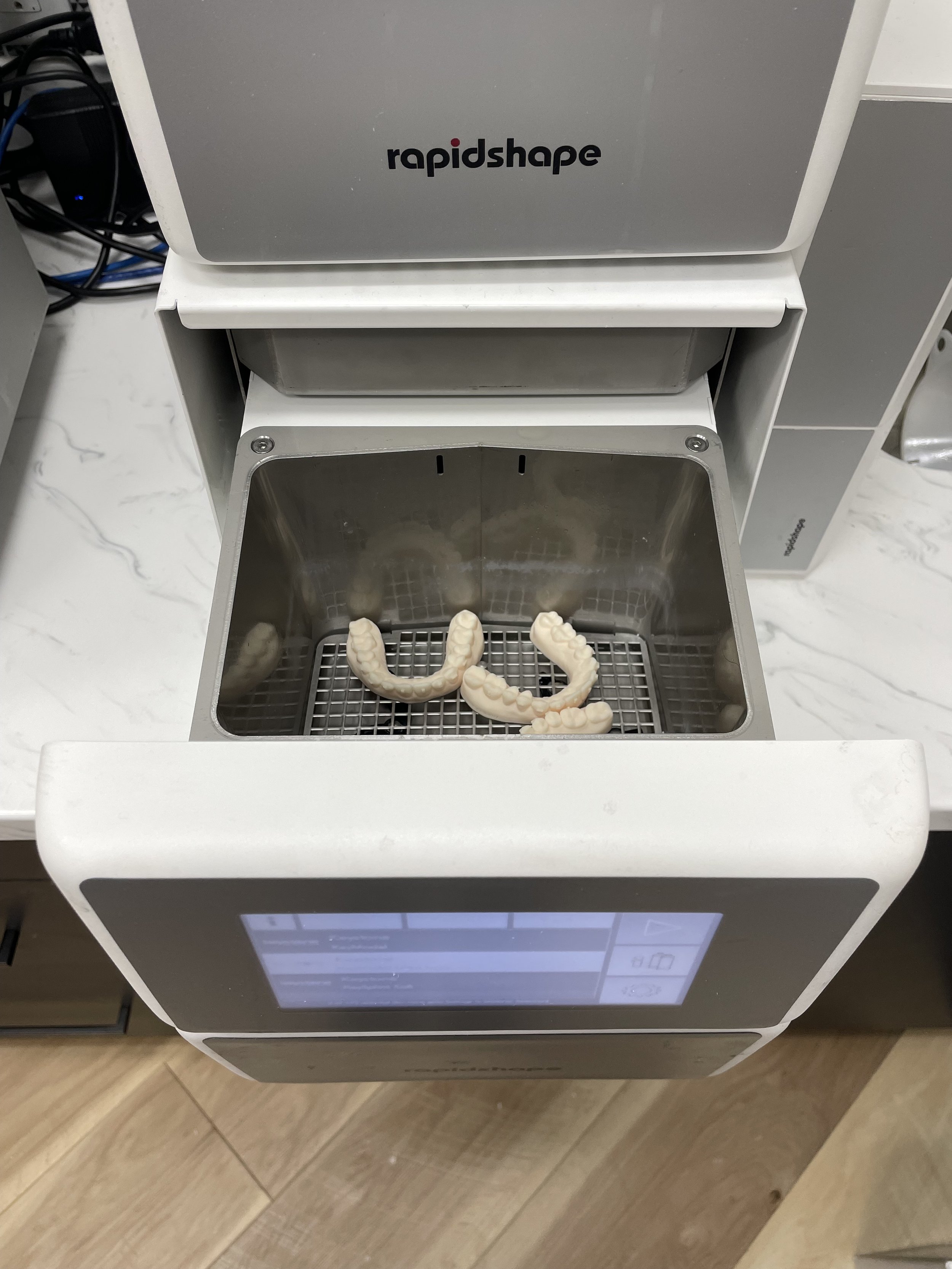

Once it's done printing, it goes into a wash station, with 99% alcohol. It takes about 10 minutes to wash. Then, it goes into a cure, which looks like a little tanning bed and takes 5-8 minutes to cure into a state that it doesn't move any more.

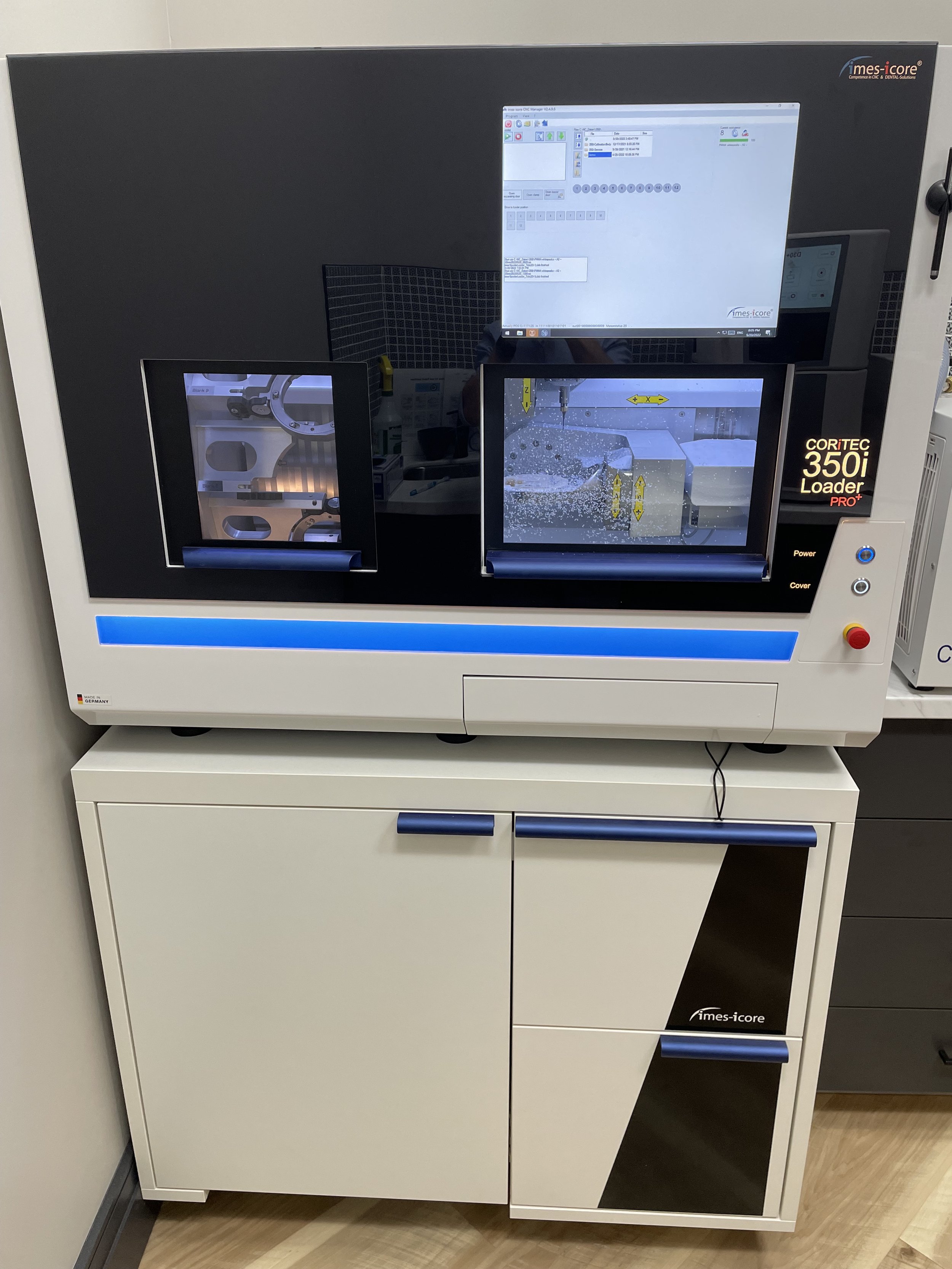

Then, we have our iMes iCore milling machine, which mills crowns, bridges, basically anything you can think of. It has a little box at the end that’s like its tool box. There’s a bunch of different bits used to frame out a crown. It takes about 20 minutes to mill a simple crown.

The next machine is called a dental furnace, used for zirconia, which comes very big out of the mill in its green state. Once it goes into the sintering furnace, it shrinks down to fit the mouth. It takes about 5-7 hours at a very high temperature to sinter the zirconia. I usually stain the tooth first and then put it into the sinter and then polish it afterwards.

We’re making our own ortho aligners too! We design in-house, print the models and then vacuum-form the actual aligners. We trim it here too. The Ministar trims the aligners and polishes the night guards. Nightguards, bleaching trays, and ortho fabrication have improved so much with these new technologies and machines.